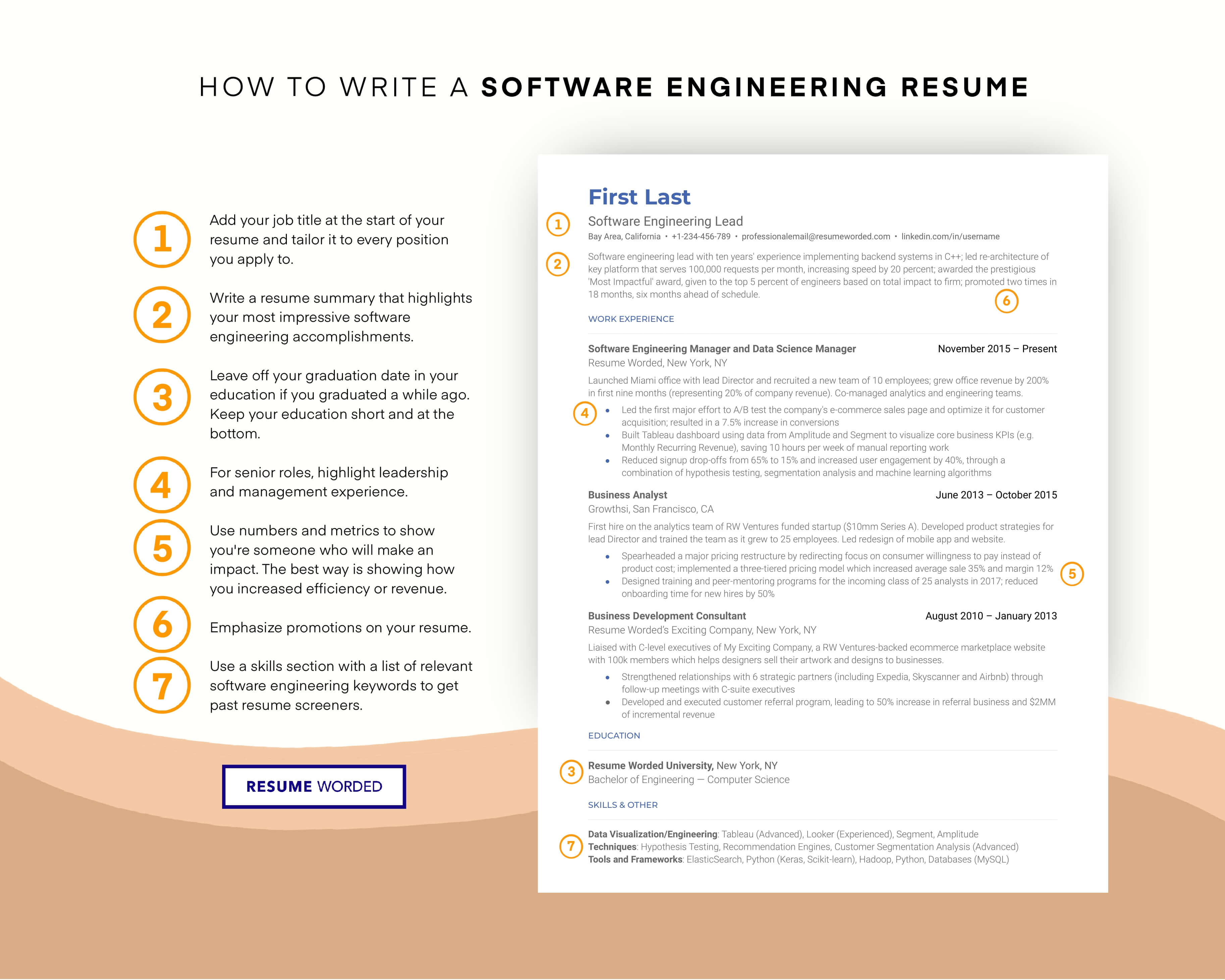

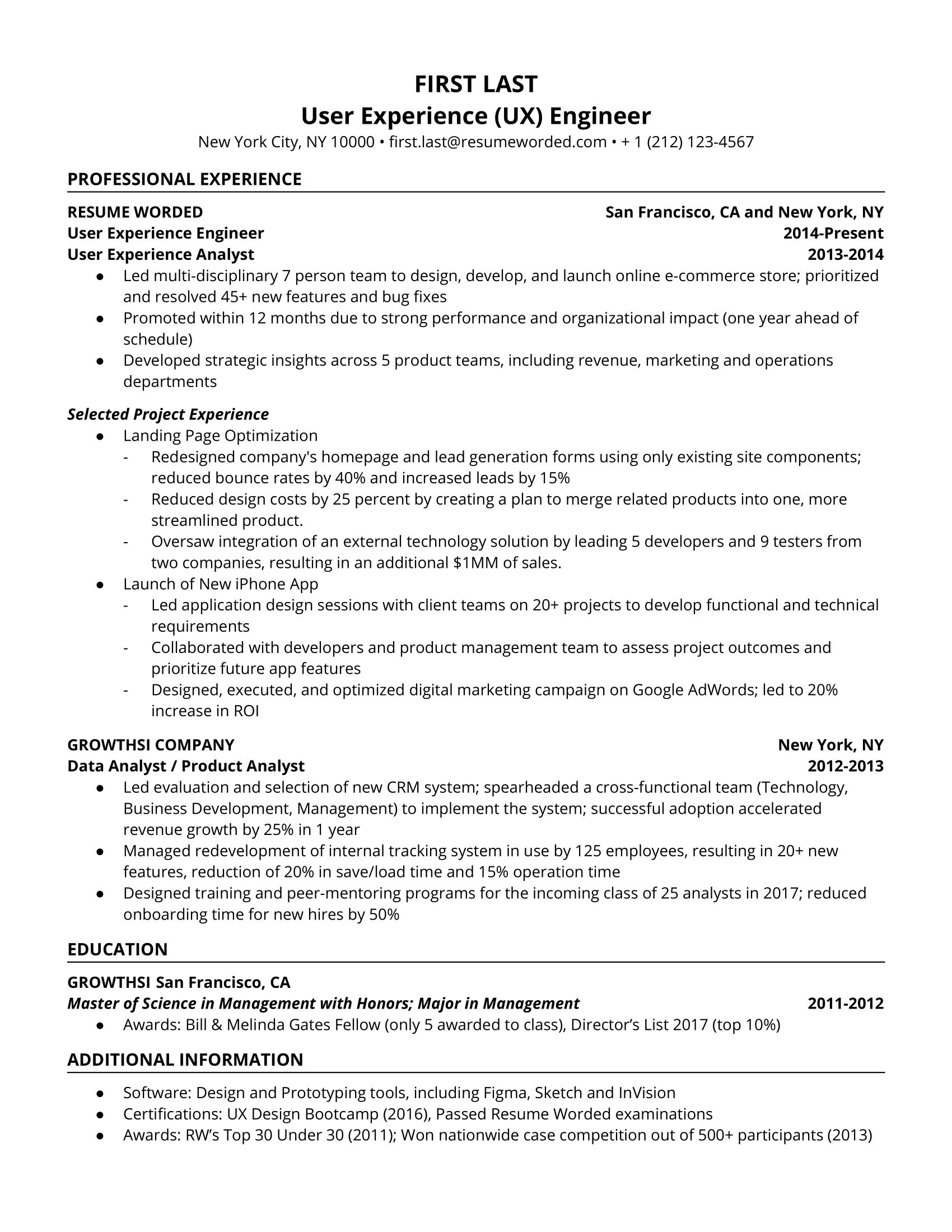

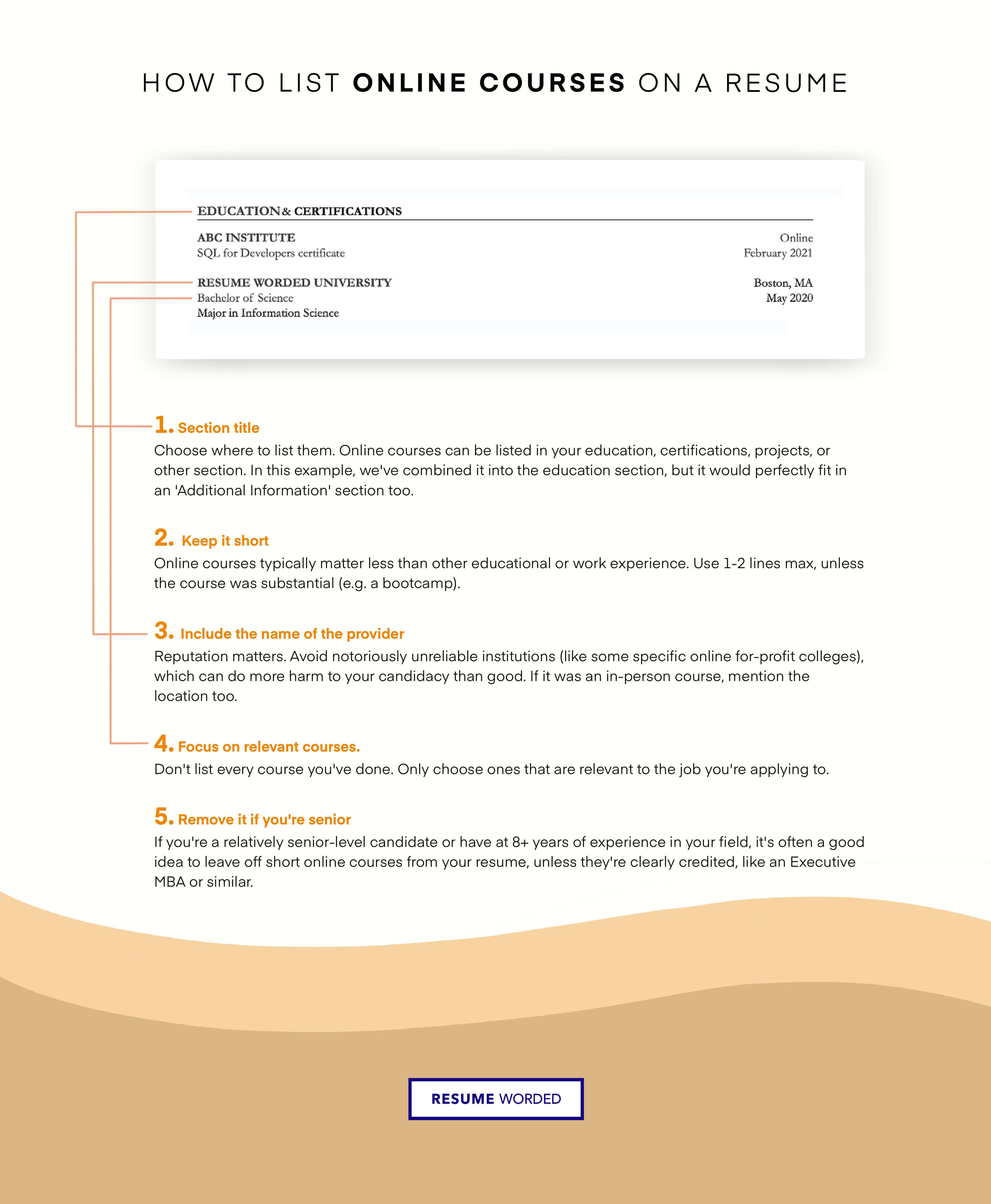

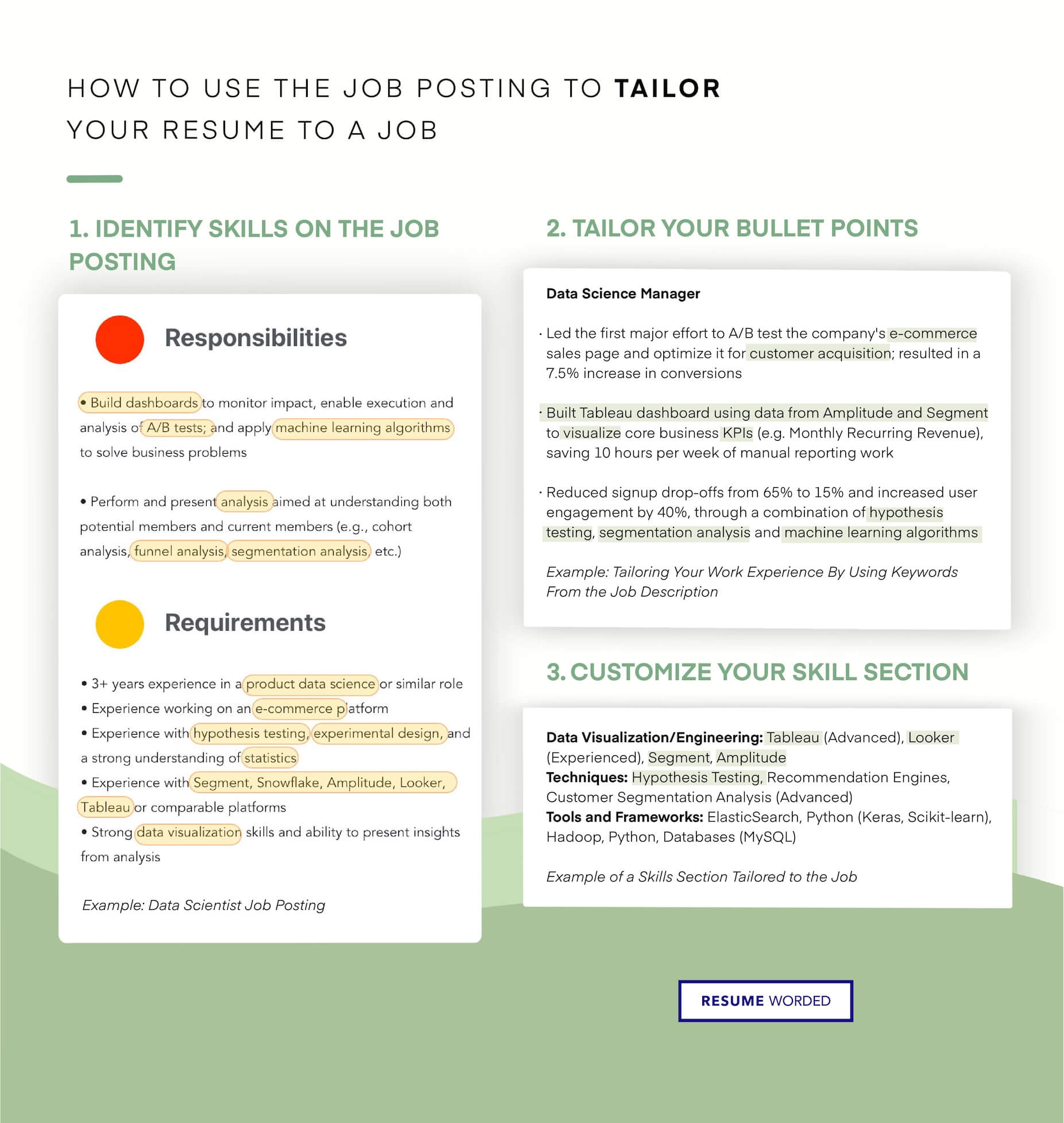

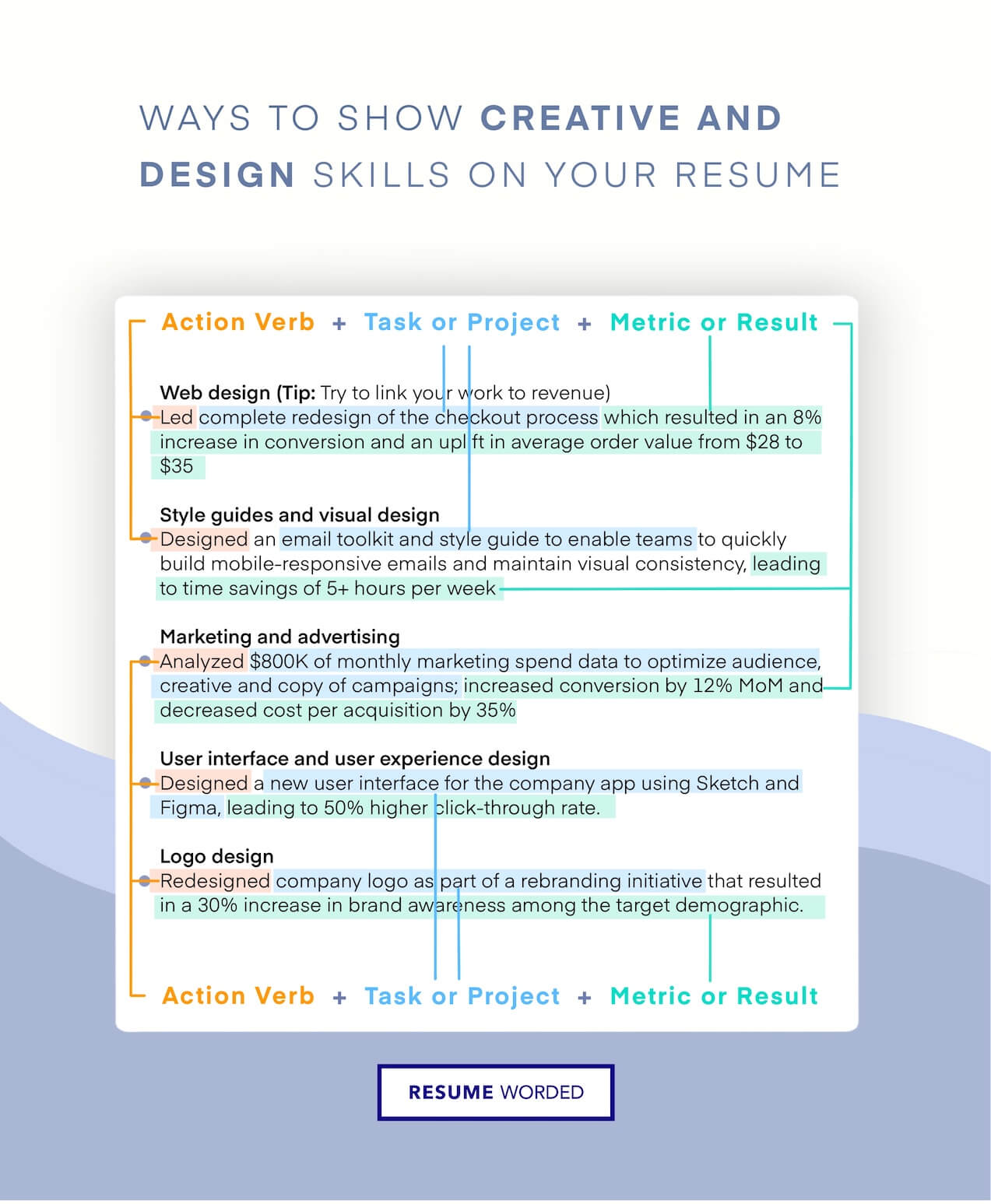

Focuses on hard skills relevant to UX engineering

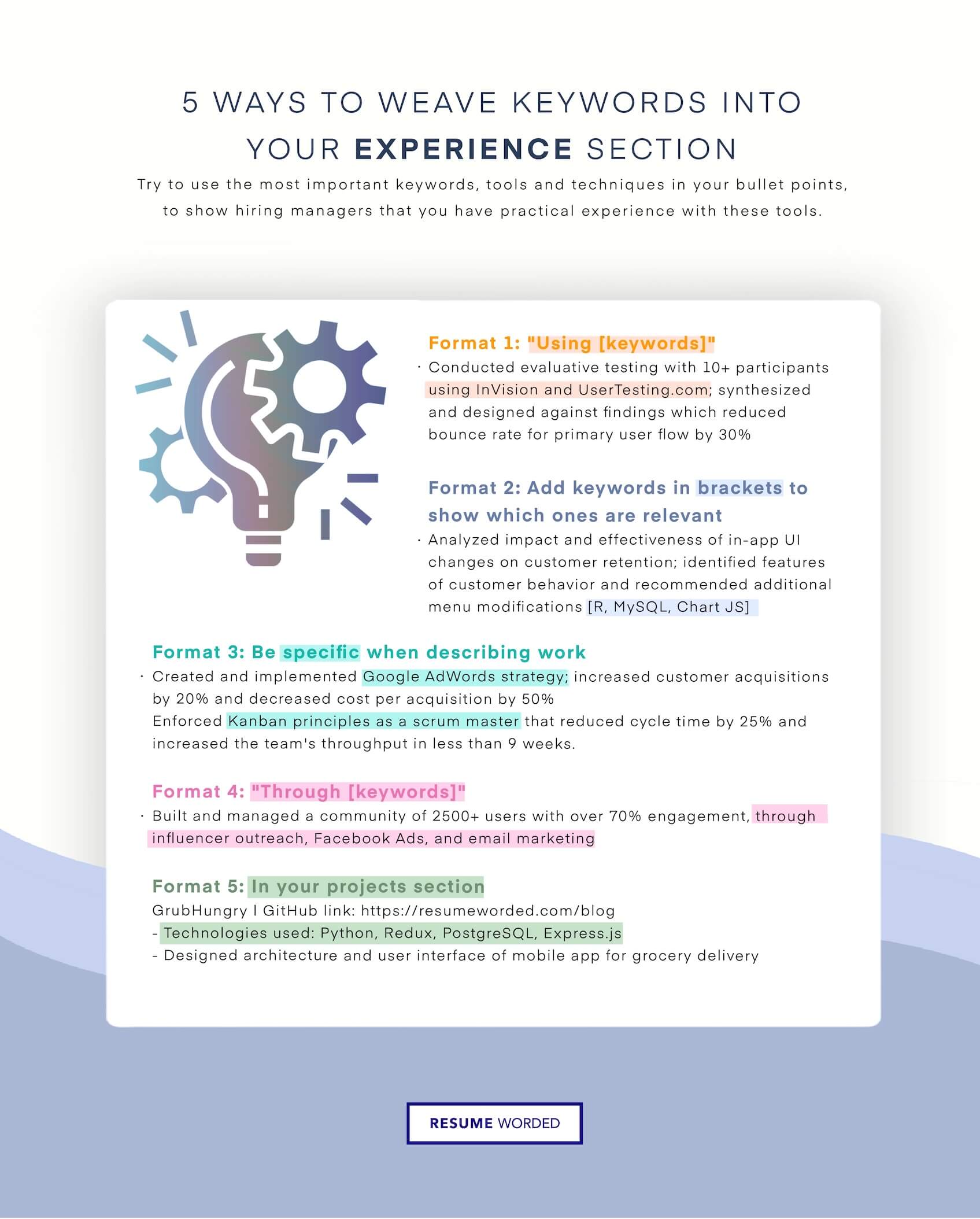

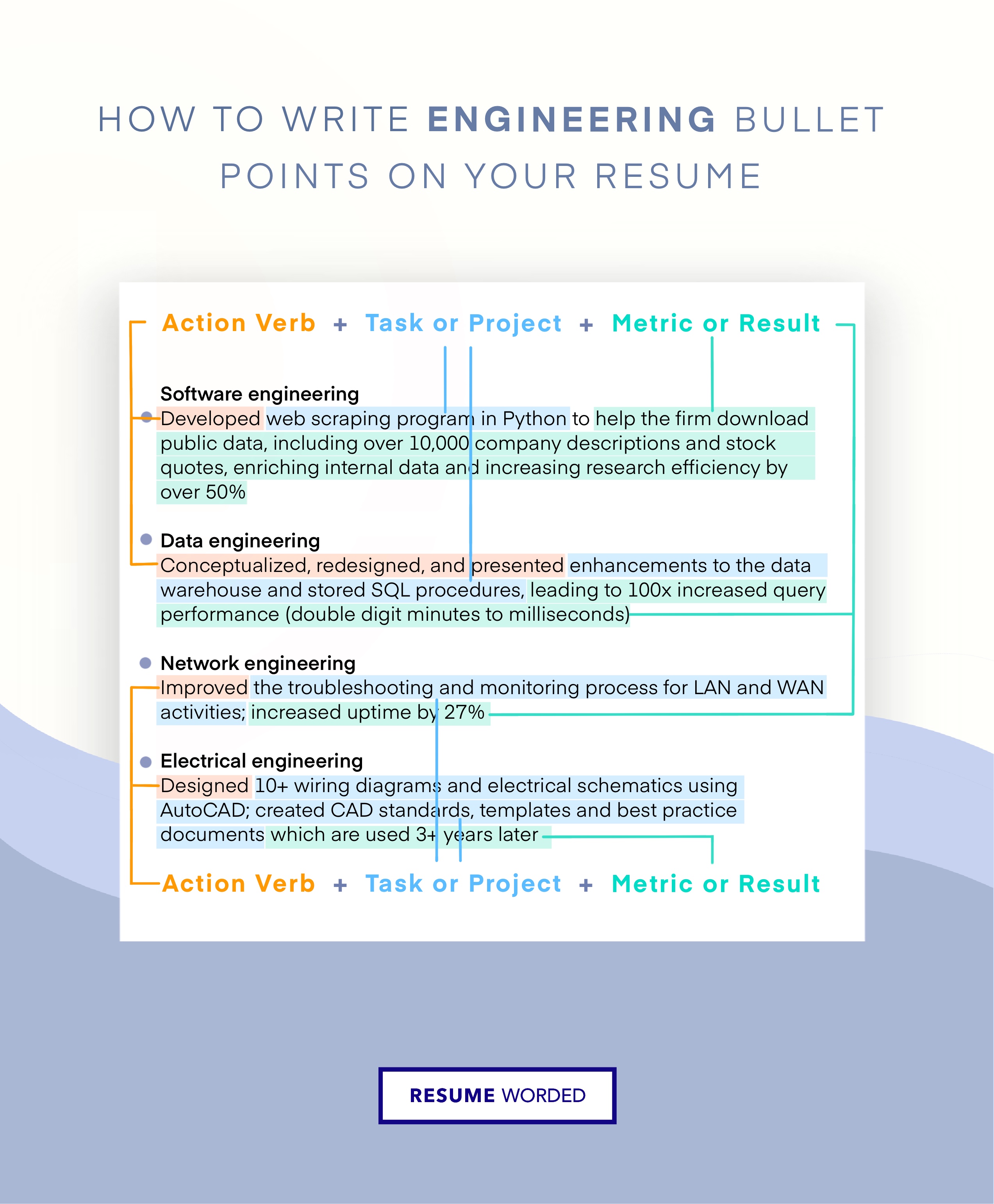

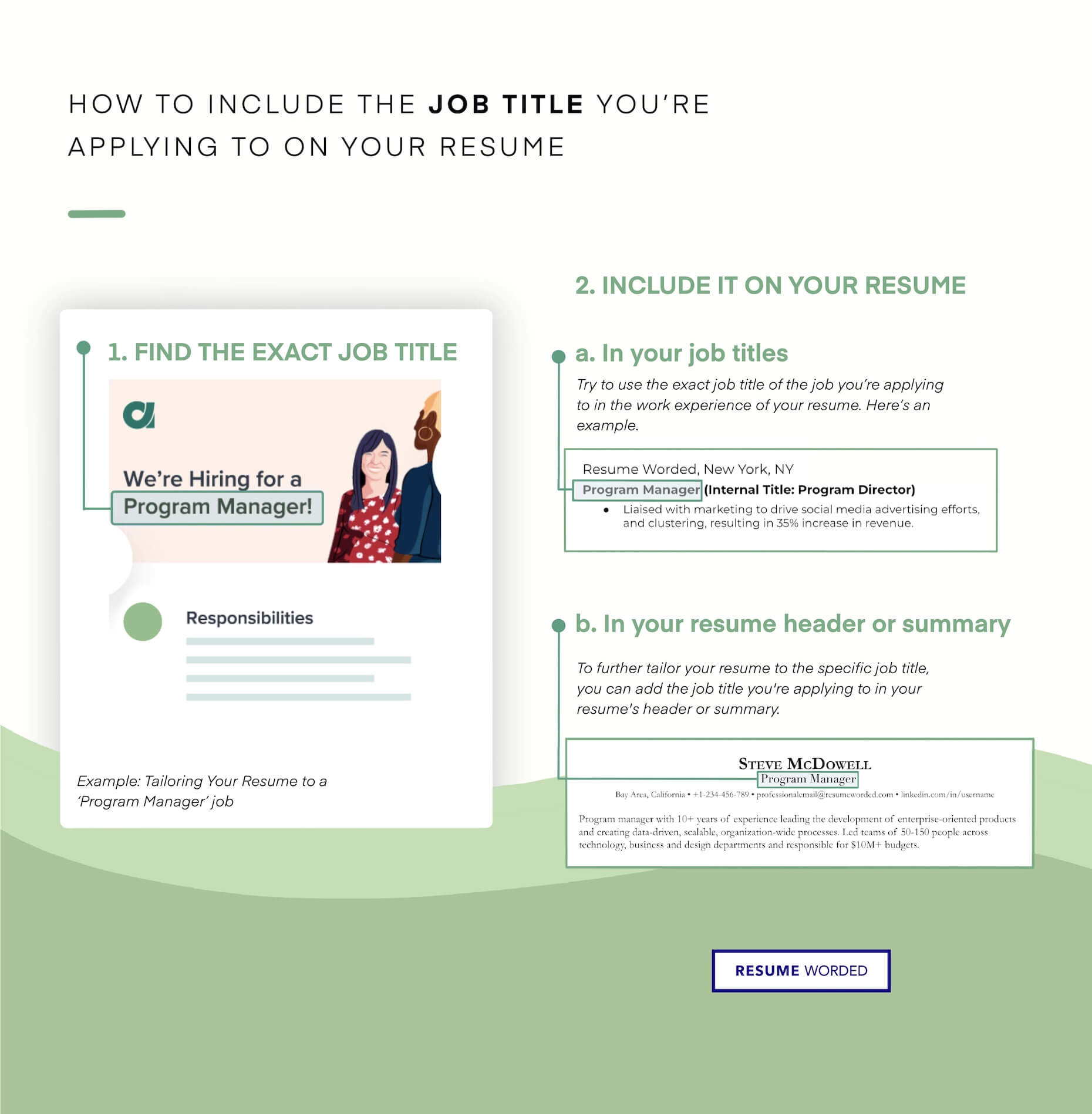

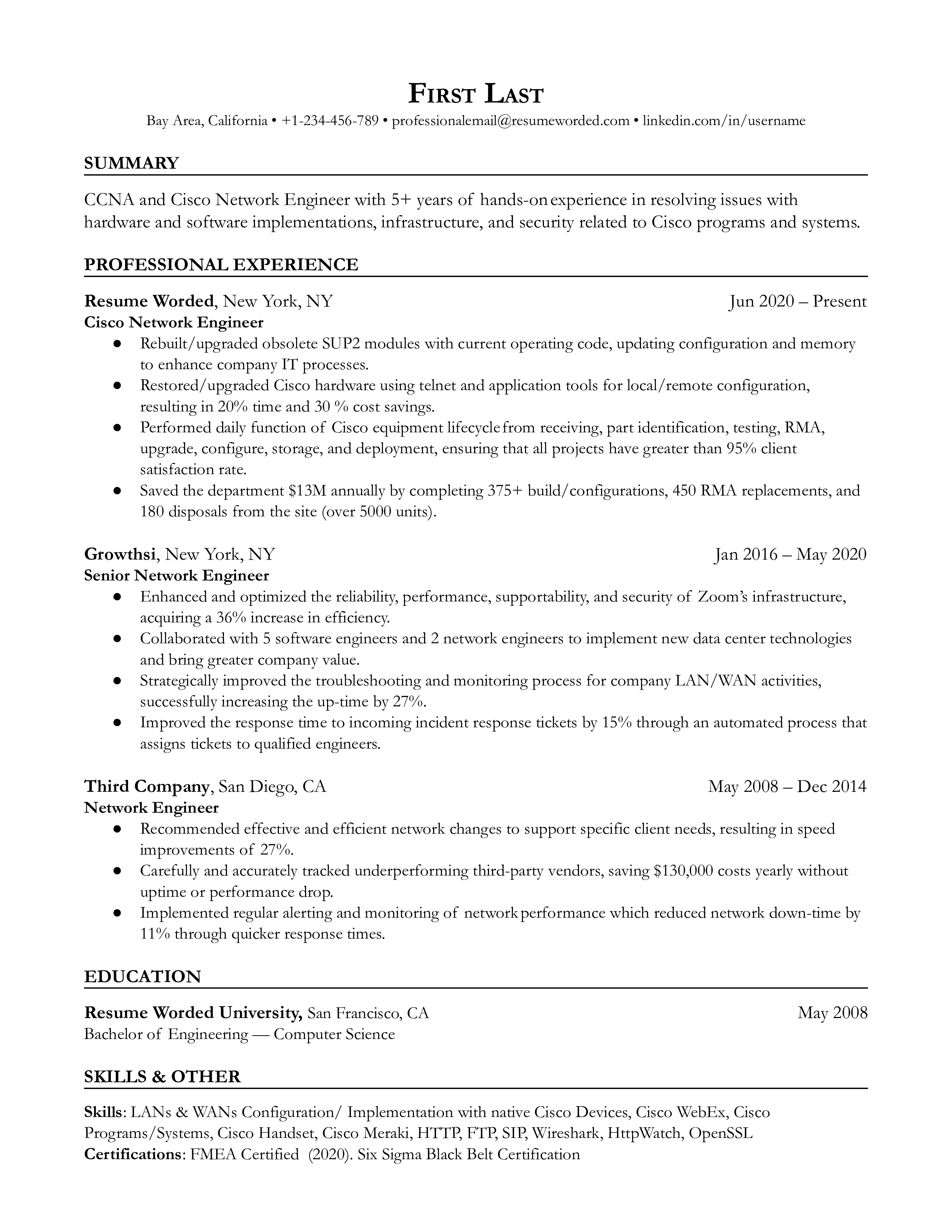

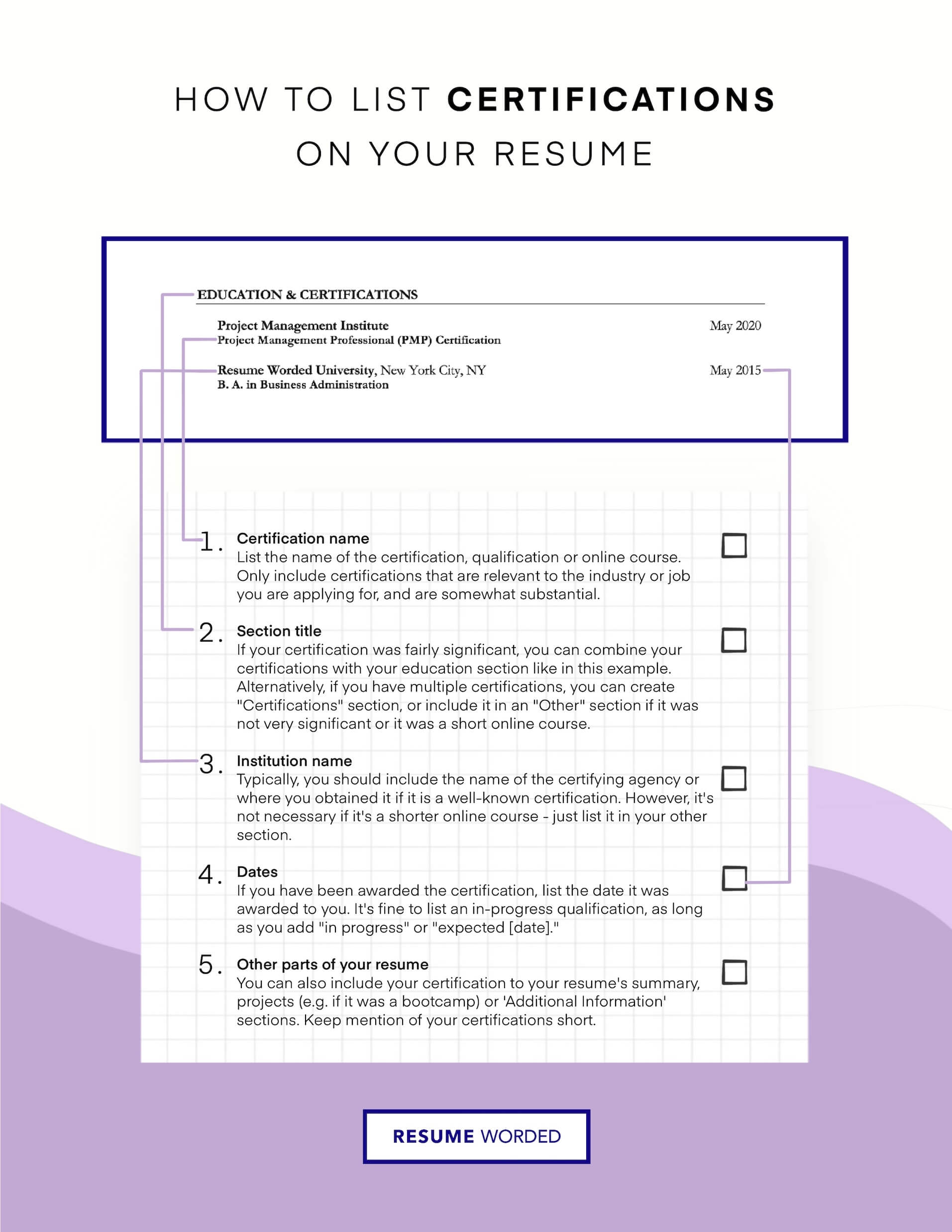

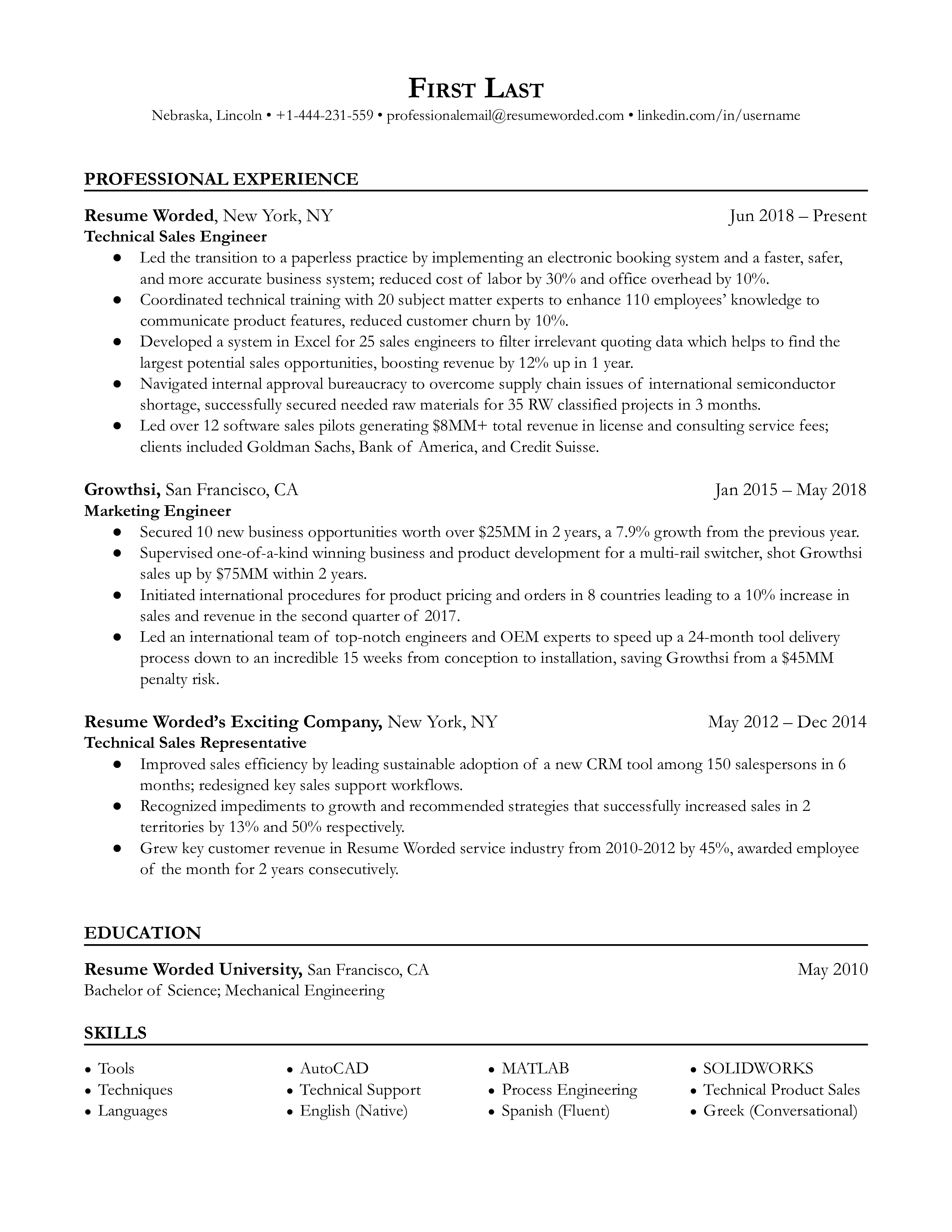

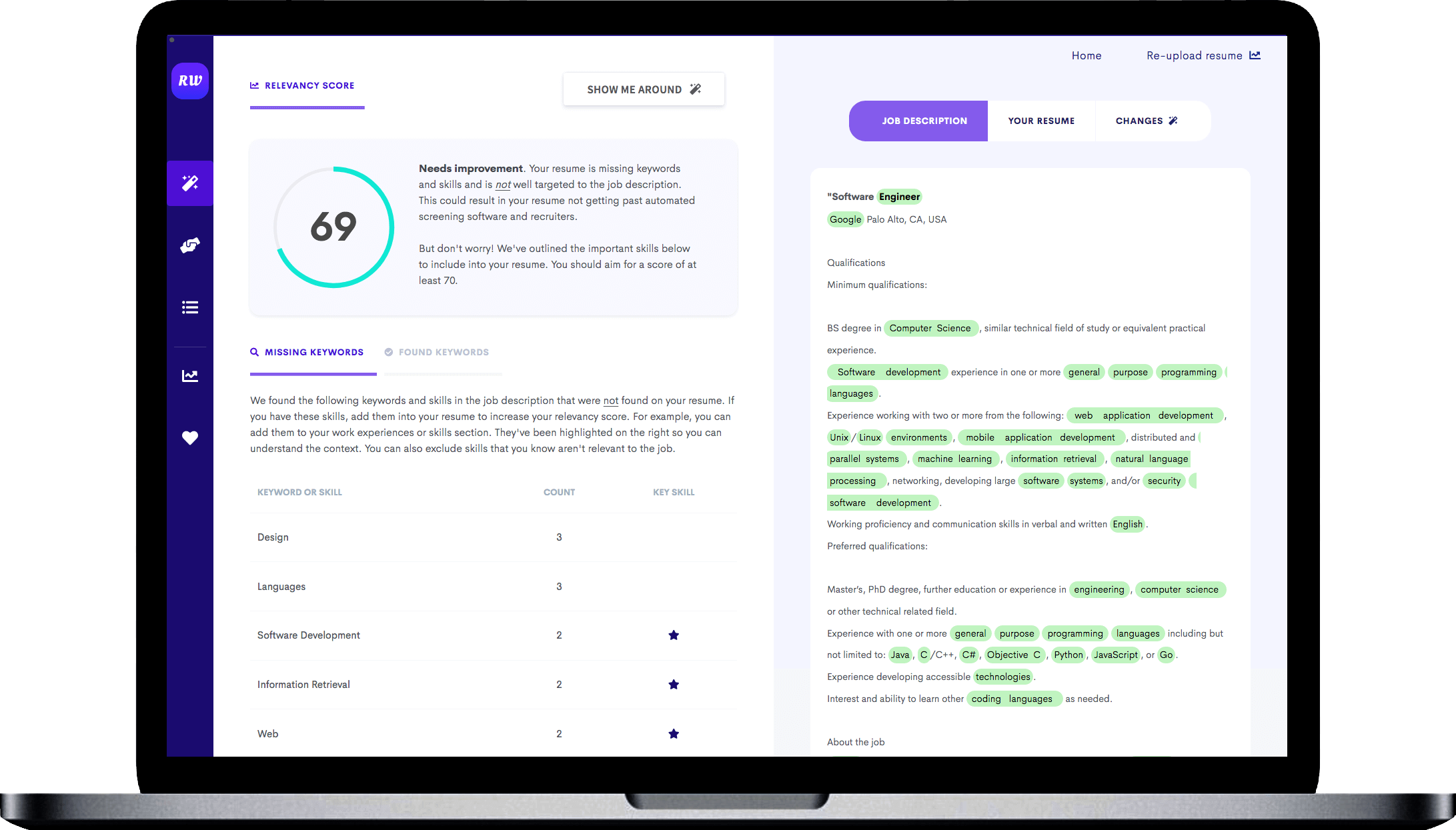

UX engineers need a lot of technical skills, so make sure you explicitly list skills and keywords. This is just as important for getting past a resume screener as well as showcasing your fit to a hiring manager. You can include hard skills and certifications in your work experience bullet points or in an additional skills section.