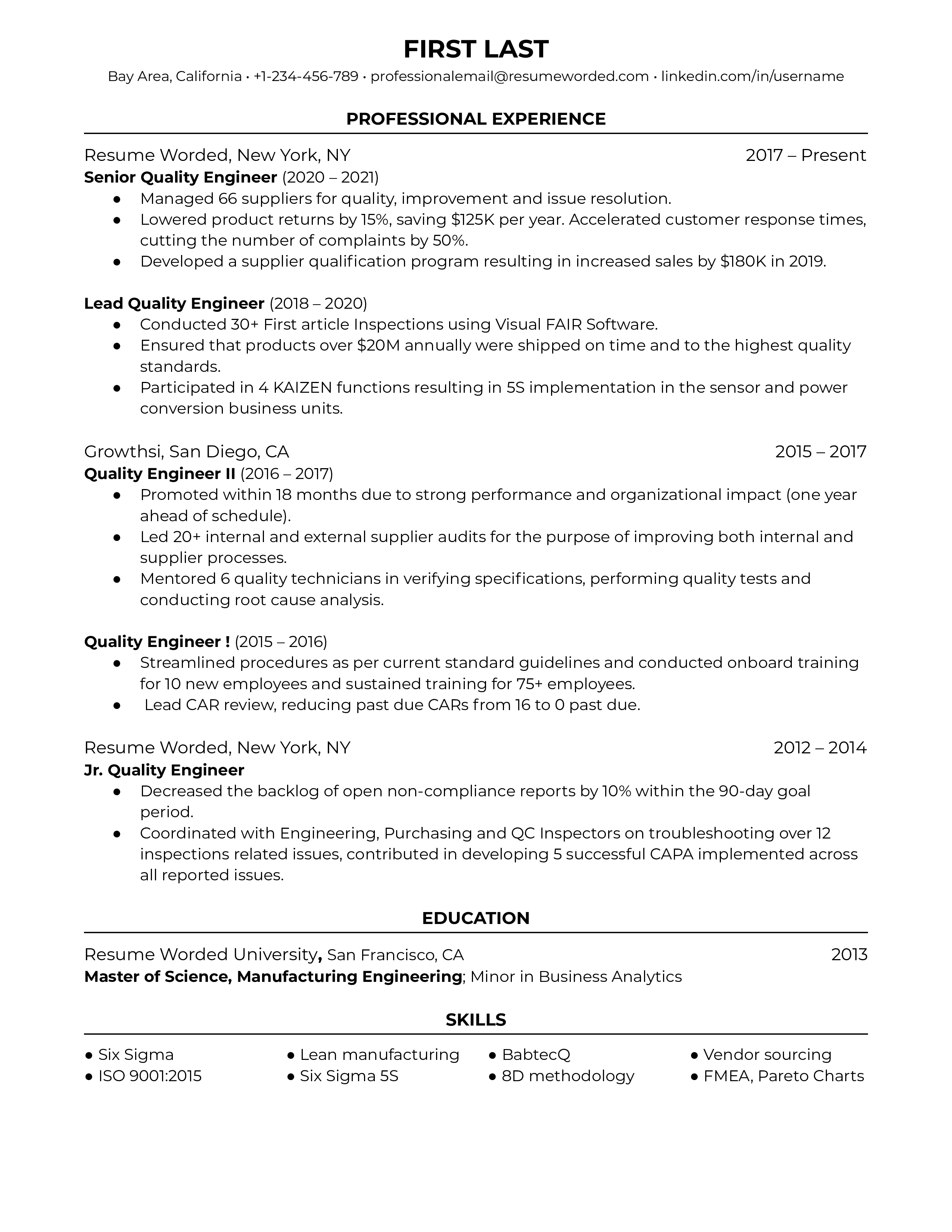

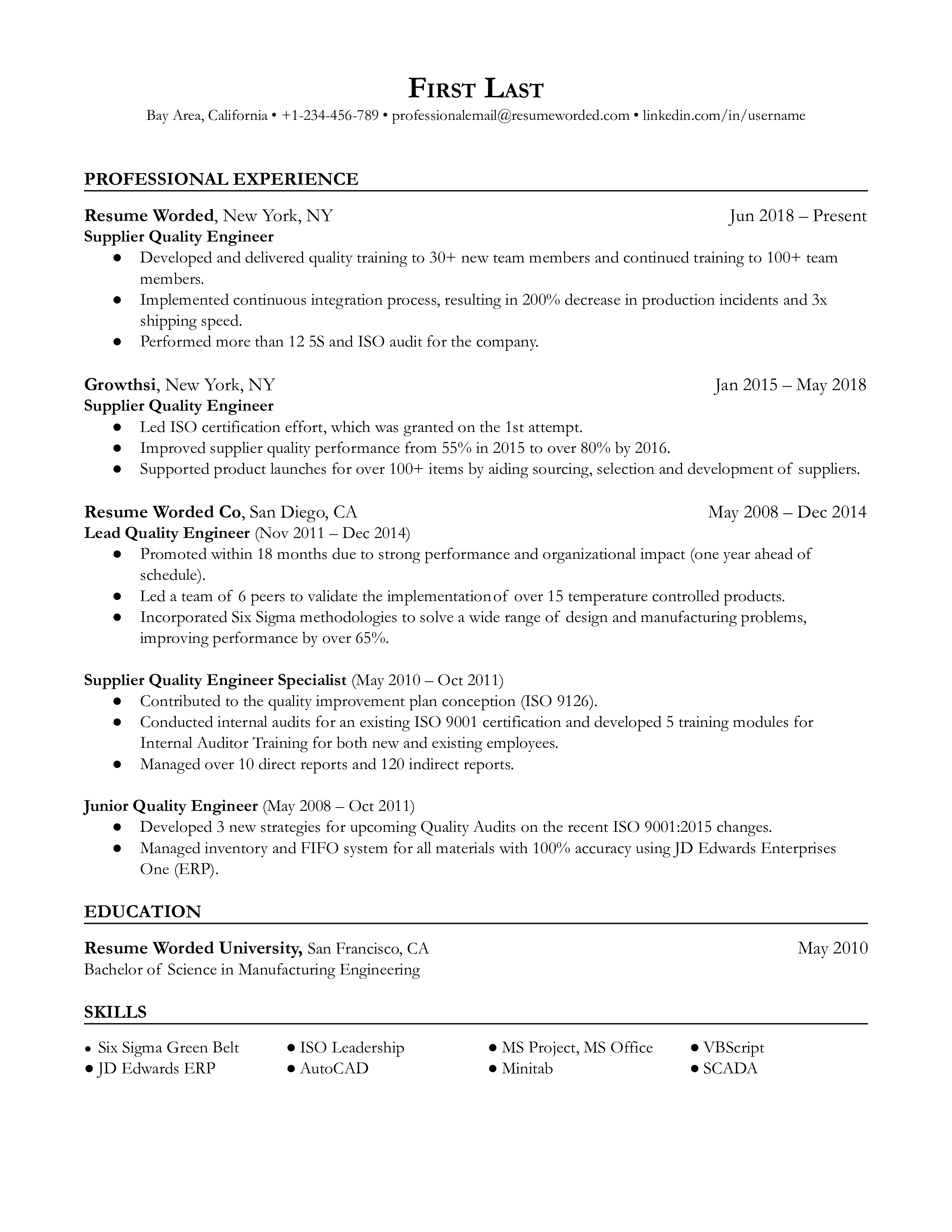

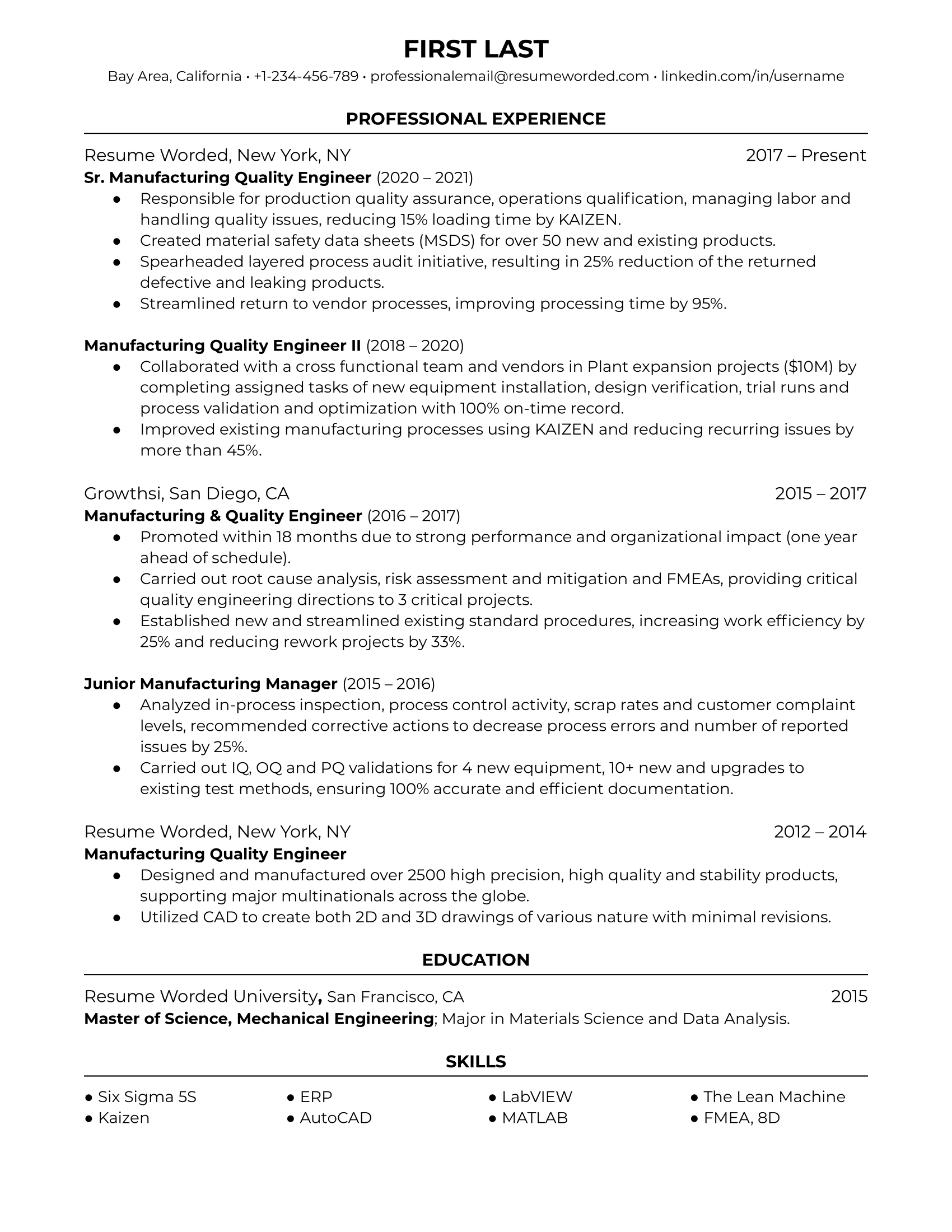

Adapt to the specific Quality Engineer role

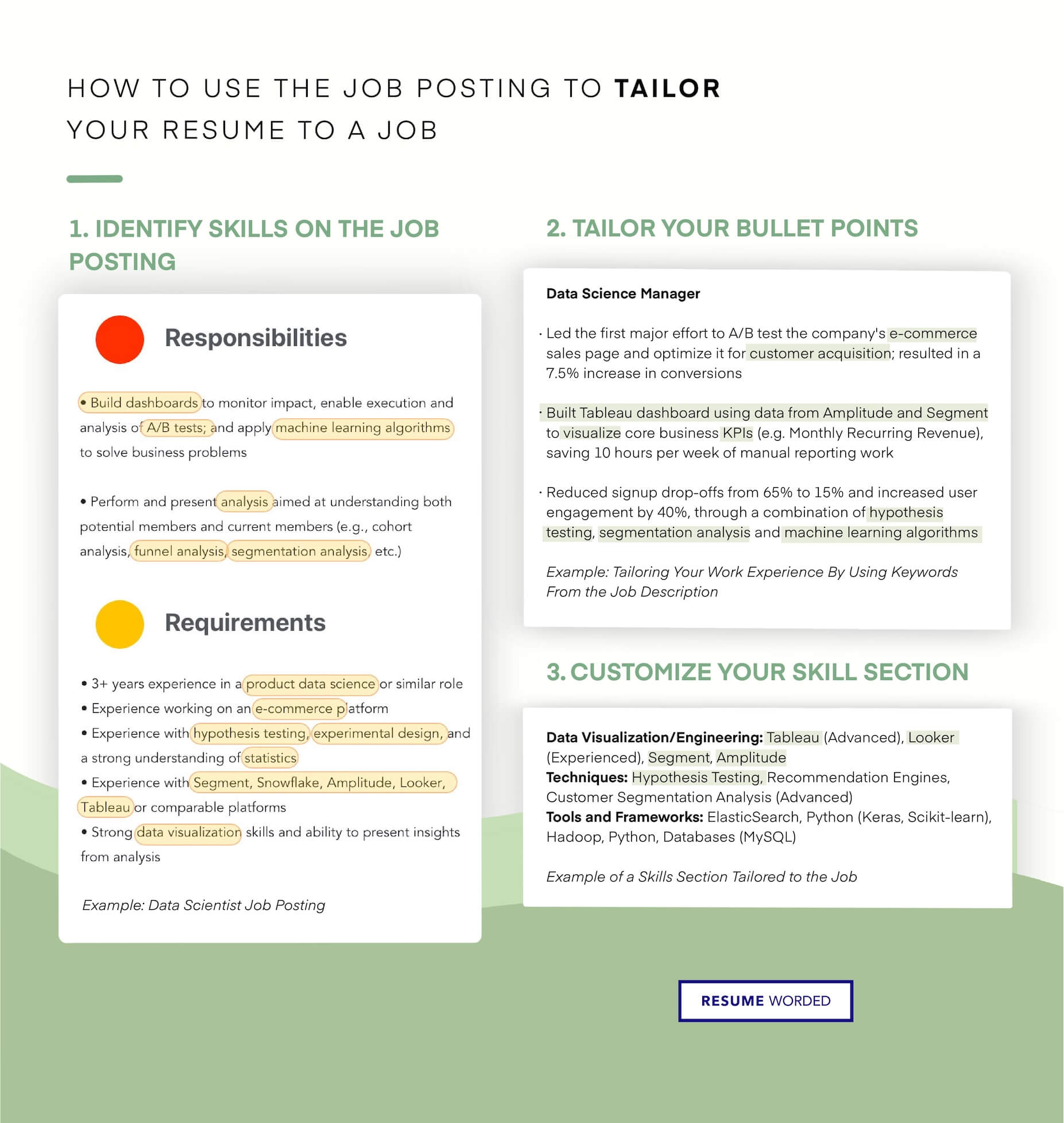

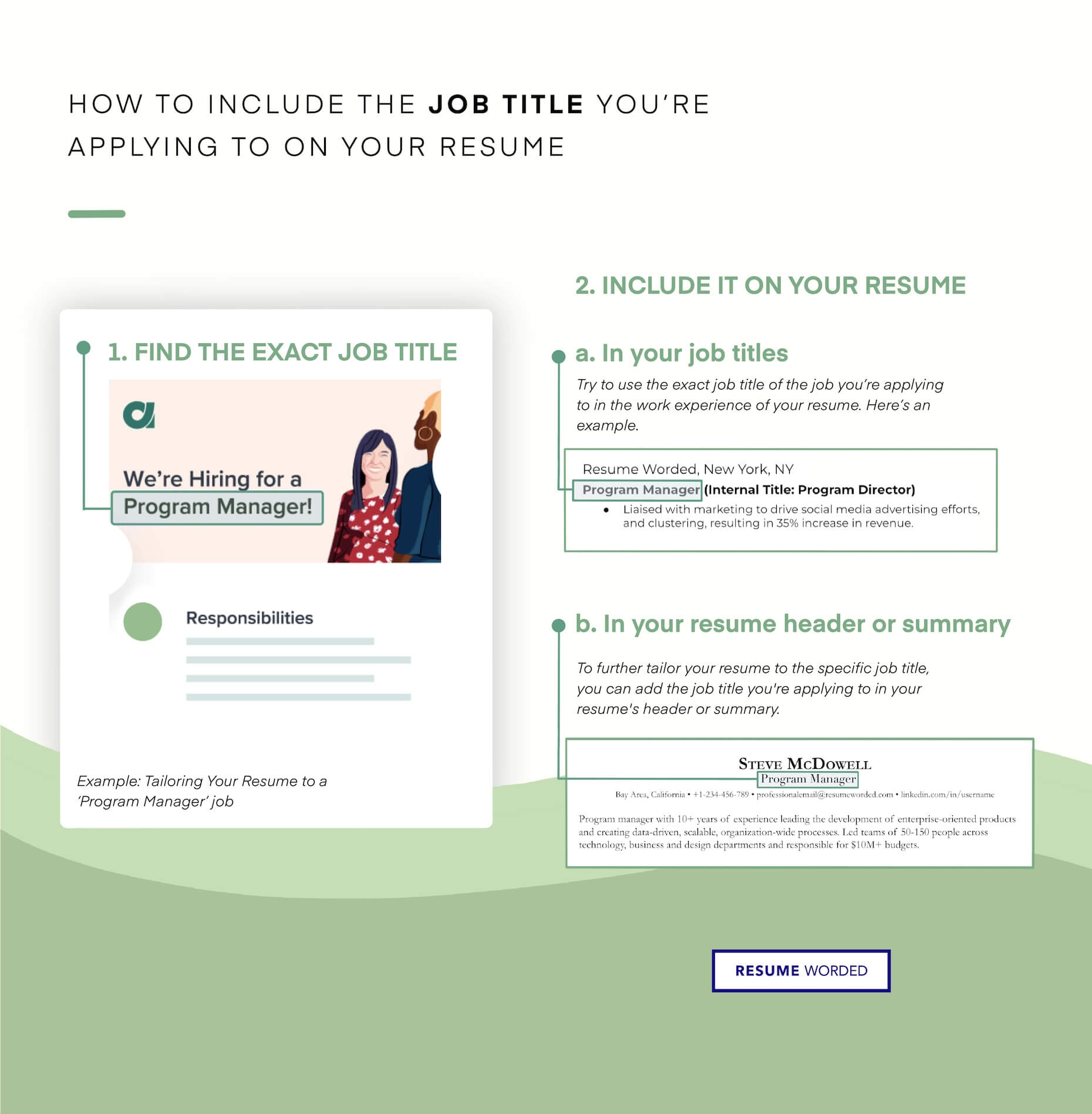

Make sure that you are adapting each version of your resume to fit the specific job that you’re applying for. If you had previous jobs with different titles, try to match them as much as possible to your next position. In this resume, each previous job has some variation of the words, “Quality Engineer” in the title.